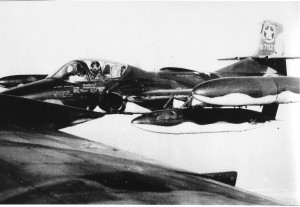

HIGH power taxi test

Well, for the first time I let my A37 go all out. 98-100% power on a taxi test at KTMB. Short-term full throttle due to the fact the plane accelerates so quickly to flying speed.

Had my son along to monitor gauges and speed. I think I could see his smile through the mask 10 minutes after we came back to the hangar and shut down. He was grinning from ear to ear.

No surges, no fluctuation, no problems. Very smooth. Power response was perfect and aligned. And with a 1 to 1 thrust to weight ratio, I pretty much felt what so many others have written about. This bird is going to be a dream to fly.

Ground handling was straight and true. Taxi on one engine saved fuel, noise, and money. Only slight constant foot on the steering to keep ‘er straight. Used much less brakes ($$).

Acceleration was VERY quick! From zero to 90 kts. in about 6 seconds. She wanted to fly. But I had no flaps on her so she sat on her legs properly. Any flaps and she would have gone airborne.

Tower had good things to say about the new bird on the field. “She looks real good out there”. Kinda made me feel good too.

Later

First FAST taxi

Well, got the aircraft out of the hangar this morning for some high-speed taxi tests. It was great that everything went as it should, almost 100%. The bird performed flawlessly.

Only issue was a right-side oxygen regulator that got stuck in the closed position. The mechanic/engineer in the right seat couldn’t use it and did not know how to turn off the hot mic. So I had a lot of background noise with his mask off. And the airplane is loud.

One thing I am going to start doing is taxiing on one engine. Two-engine taxi runs eats the brakes, consumes way too much fuel, and doesn’t do a thing except burn dollars. The mechanic doesn’t like that, but he’s used to much bigger prop driven planes. I don’t need differential power for steering or speed. Hell, it’s too fast as it is now.

No radio issues. All OK. First taxi was moderate to 50 knots to check steering and brakes. Then back around again for another. This time I held the brakes until 60% and let ‘er go. Power up to 80%. Even with that little bit she took off like a shot. Up to 70 knots. All OK. Don’t really need to use power steering above 60 knots so I have to learn to turn it off as I accelerate.

Even with power at idle it does not like to slow down. So thrust attenuators are a must. Next power runs I will shut one engine down on runway as it slows. Brakes are adequate, but certainly not going to write home about them. Just have to get used to the quirks of the bird until it is natural to the touch. Right now I am “thinking” about everything, and that’s not the way it is supposed to be done.

So, we put the plane away after 50 minutes of ground work, radio checks, accellerations and stops, steering, engine instrument checks, system checks, etc. All perfect. And I used a lot of fuel just doing the taxi runs (2). Figure about 125 gallons. OUCH! It’s a hell of a lot more efficient in the air.

Sweet Engine Sounds

With the starter back in, it was time to turn them over and burn some fuel. Starts were prefect and cool. All gauges readings perfect. No problems. So maybe time to drive it around. Boy, is that bird LOUD! Will have to be careful when operating or else I am going to annoy some neighbors. You can feel the bird just trying to break loose, even at idle. (By the way, it is best to taxi on one engine–too much power).

When we pulled the bird out of the hangar and lit her up, we had gathered a small crowd of gawkers. They came out of nowhere with cameras, still and video.

Left brake was “squishy”, if there is such a word. Decided to investigate before driving too far. Found a small hydraulic leak in the copilot’s master cylinder swivel inside cockpit (a common problem with these swivels). Took some time this weekend and pulled it out and repaired, then re-bled the brakes, filled master cylinders. Now looks and feels ok. Seeing as the bird was on jacks we did gear retractions, checked the gear horn, cycled all systems, etc. Perfect. Was dead tired after two days of tool thrashing, so we quit yesterday with almost half a day remaining.

Will do high speed taxi next. Will try to do this week, rather than waiting for weekend. Holidays coming up so time is squeezed for all of us. With family coming in, it would be great to do some taxi tests with someone who can write down engine indications, call out ground-personnel checklist, etc. One runway is closed at KTMB which may be a good thing. I may be able to use it for taxi only without bothering local traffic.

If for some reason I do not post during holiday, may I extend my best wishes to you that are just “plane crazy”. May you have tailwinds and other good fortunes, all.

Charlie (Dragon 921)

Starter In, Intercom fixed

Rebuilt starter went in (again!!) today. All locked up. And, took apart the intercom. The radio guru was able to rebuild the transmission amplifier. It works perfectly.

It was interesting–the radio issue. The microphone/earphone cable, (4-wire), is unshielded. So it puts out a lot of RF. It jumps right into the transmitter with a loud squeal. The amplifier fixed it. But I would have thought a shielded cable would work almost as well.

Next time I’ll replace with a new type of shielded cable to eliminate any feedback.

I was able to change the squeal by simply running my hand up and down the cable. Learning new stuff all the time.

The Classic Jet Aircraft Association has an upcoming annual convention in March at Nellis AFB, Las Vegas Nevada. March 17-20. My bird won’t be there but it is a good group. Hope to see you all there.

Starter Problem

During pre-flight I have always spun the turbines over by hand to ensure no binding. Well, I’ve had this problem before and thought I had it licked. But the right engine was stuck, and I knew why. It was melted varnish from the stator.

This has happened before and we finally worked through it. But it appears there is still some residue varnish in the stator that has leaked in between it and the armature. So I pulled the starter and sent it to the shop for warranty repair.

YEP! Same thing. They’re as flumoxed as I am about this. Will get the starter back in this next weekend and turn it over.

Wired! MAN, YOU GOT ME WIRED!

If anyone thinks the slow economy is not a “trickle-down and affect everyone” theory, go back to school! Even outfits that normally sell certain wires from stock don’t have them. Production is slow everywhere. But I found the wire, ordered it, and it came in finally in three shipments.

So it is off to the electrical guru for the nav harnesses. Know its been a long time.

Had a friend in town the other day, a memer of CJAA. Owner of probably the finest L39 anywhere! He and I spent this Tuesday buming around and he got a chance to check out the A37. He asked all the right questions, fuel system info, power and weight ratios, etc. Anywho, he’s on the short list to check out in the bird when its finished. However, for some reason, he doesn’t want to pay the fuel bill for a long period of time. Nope. No way!

“That thing is a dinosaur pig!” he exclaimed.

“Well. DUH!” The reason the thing is so quick is that is overpowered and light to begin with. Enormous “off the line” dragster type performace. Not fast, quick.

Another CJAA guy who flies the A37, Dave, says its out of the hole performance is astounding. He really enjoys the bird. Once flying, simple and straight forward.

A couple of weeks before I can get this harness connected and the bird “rebuilt”. I got pieces of it all over the hanger, wings, UNDER the wings, on tables, rolling carts. Everywhere. But, I should finally get it together soon.

Still looking for the Andrea Intercom micrpohone amplifier. Trying to scarf one up somewhere. It won’t keep the bird on the ground because it will be on the copilots side.

Taking time to do it RIGHT!

Throughout a restoration like this, one has to put faith in people who have particular skills, such as radio wiring. And it is more than a little discomforting to find the faith was misplaced.

I have finished the intercom re-wire and found everything to be in order except for one internal microphone amplifier which needs replacement. But first I have to FIND that replacement. Beyond that, I (we) found some poorly designed and assembled VOR wire bundles. So out it came. It is being re-wired now with new bundles and plugs, fit and installed properly. Screw this tie-wrap assembly crap! Correct Adel clamp securing will replace the old stuff.

While this sounds rather easy, I had to disassemble the pilot’s panel and instruments to get to the wire bundles in question. (the ejection seats and center console radio and Ox system have already been removed for this). Then remove some fuselage fairing in front of the windshield that is always a pain to R and R due to its 87 -832 flush screws. One step forward, 10 steps back. When this is completed, I hope to put everything back together and let her rip!

Can someone tell me how you can drop an Adel clamp within a limited space and LOSE IT? How can it disappear like that? Hours searching for a damn nut or clamp and it vanishes right in front of you. That makes (I actually keep score on this!) one Adel clamp. two 1032 nuts, one razor blade in the cockpit. When the bird gets into aerobatics I will carry a trash bag and mini-magnet to collect the wayward articles. Uh, copilot, would you hold it inverted for a minute while I collect this trash from the canopy? Thanks. Now let me vacuum everything up.

It’s going to be a few weeks before everything gets back together and assembled correctly. Jeez, I hope there are no more surpirses. My DAR is pissed off at me!

Tough Electrical Issues on Radios

Well, I’m back to an almost completed airplane after building a new radio harness for the bird. Rather than try to keep “fixing” things, I decided to pull out the intercom/radio harness that is within the cockpit and replace it completely–new cannon plugs, wire, etc.

The problems were numerous and confusing: scratchy noise, feedbacks, blank-outs, intermittent coms, etc. Seemed to come out of nowhere. Anyway, with the complete new harness soldered in, we fired her up. Damn thing still acted goofy. Through trial and error, we found that if we removed the “required” inline converter (military to civilian) for the mics, 90% of problems disappeared.

Anyway, both sides work now, except copilot cannot transmit on VHF coms. He can hear everything, speak over intercome, etc, but just can’t talk with the ground. Looks like the internal RF filter and mic amplfier in the box is bad and must be repaired or replaced. Looking for replacments now.

So if ANYONE out there knows where I can come up with a couple of spare T37-A37 boxes, let me know. By the way, these things are actually on a LOT of Air Force birds, including C130s. Unit is C-2106A/AIC-18 (Andrea A81-13-1).

Will add photo of intercom later.

The silk screening on the faceplate is irrelevant. It’s the box button positions that count here.